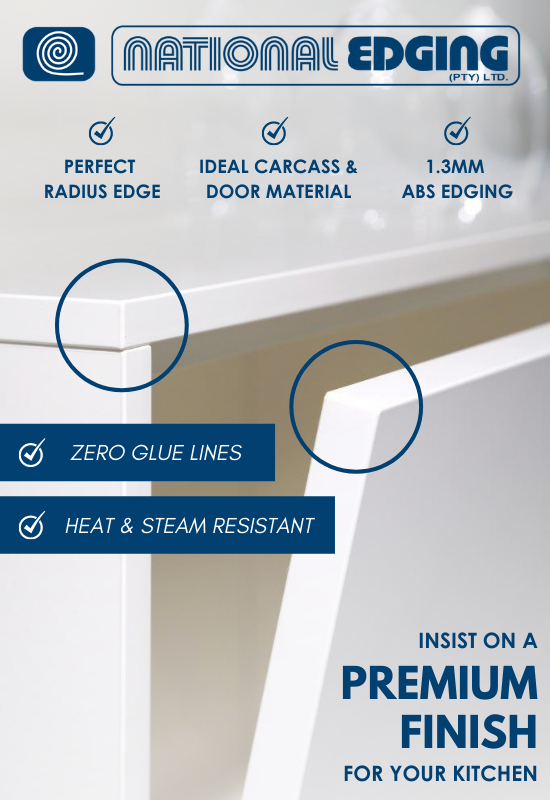

Insist on a quality finish for your kitchen

At National Edging, we pride ourselves in delivering the highest quality kitchen components to our kitchen suppliers. Working with a comprehensive range of internationally-accredited materials, we are committed to a premium quality finish with every project we produce.

Insist on a quality finish for your kitchen.

What is the correct impact edging to use in a kitchen?

ABS (Acrylonitrile Butadiene Styrene) is an impact, abrasive and thermally resistant, high quality thermoplastic material which is also ecologically sound with a high UV resistance.

What do you mean by impact and abrasive resistant?

Dollken’s surface printed ABS is sealed with a UV hardened acrylic varnish to give superb scratch resistance, as well as resistance to all standard domestic cleaning agents, meeting European standards DIN 68861, Part 1 and Part 2.

Why would you need a high UV resistance edging?

Modern kitchens are generally open plan and exposed to a variety of light sources. Dollken’s ABS meets the light fastness of wool scale 6-7, and will therefore not fade when exposed to the natural light normally found in a kitchen environment.

What is the biggest benefit of ABS edgebanding over PVC edgebanding in a kitchen environment?

For the consumer, it is definitely the heat resistance. ABS is thermally stable, whereas PVC shrinks when exposed to excessive heat around an oven, boiling kettle or toaster. This exposes the edges of the board substrate, allowing moisture to set in. Besides being unsightly, this will result in the substrate swelling and leading to possible de-lamination.

For the kitchen manufacturer, it is easy processing. ABS is significantly lighter in weight and slightly softer than PVC, so the wear and tear on tooling in considerably reduced when using ABS.

Are there any other advantages of ABS over PVC?

Yes, ABS can be painted over without any priming or preparation. For painted doors, ABS edging gives a good impact resistance under the painted edge.

Dollken’s environmentally friendly ABS comes with an international ‘Green Guard’ certificate and has no chlorine compounds, making this a totally bio-degradable material.

What is the correct thickness impact edging to use in a kitchen?

For premium gloss panels and kitchen doors, a 1mm or 1.3mm is ideal – any thicker than that will reduce the effectiveness of the high gloss edge. The milled area will always be a matt finish so the smaller the milled area is, the better.

For conventional panels and kitchen doors, a 1.3mm or 1.5mm is most suitable. Both allow for a decent radius while reducing the ‘frame effect’ that a thicker edgebanding would produce. This is particularly noticeable on a woodgrain design, where the base colour is not identical to the surface print. 1.3mm and 1.5mm edgebanding ABS edges are more flexible than 2mm and ideal for contour edgebanding.

For carcass edgebanding, a 1mm ABS is ideal. The ability to radius the edge will ensure no sharp edges.

What is the correct adhesive to use in a kitchen?

For PVC wrap doors, you need a high heat and moisture resistance PU dispersion with an integrated catalyst. For edgebanding, you need the highest heat resistance adhesive possible, with a low or zero filler content and extremely good adhesion properties.

For solid timber lamination, a high solid content D3 certified PVAC should be used.

To read more on our Jowat adhesives range, follow the link below.